Nozzles

ORYCON offers a wide range of nozzles, their use can be divided into several groups according to the way of use and amount of injection material, taking into account its physical and chemical properties.

MODULAR STRUCTURE

The nozzles are manufactured in two material classes, hardened steel and hardened stainless steel.

All Orycon nozzles are designed so that each individual part of the nozzle is replaceable under normal die or tool shop conditions.

All spare parts are always in stock for next day delivery. Thermocouples can also be ordered through the e-shop.

ORYCON nozzles,

are easy to install in mold.

BCE Sprue bushings

They are suitable for injection into the cold sub-pipeline, or for injection directly into the part with subsequent adjustment of the trace of the inlet. This group is divided into 4 classes according to the size of the nozzle channel diameter 5, 6, 10, 14 and three intermediate classes with diameters of 7, 12 and 16 mm.

| Class - diameter | 5 | 6 | 10 | 14 |

| Intermediate class - diameter | 7 | 12 | 16 |

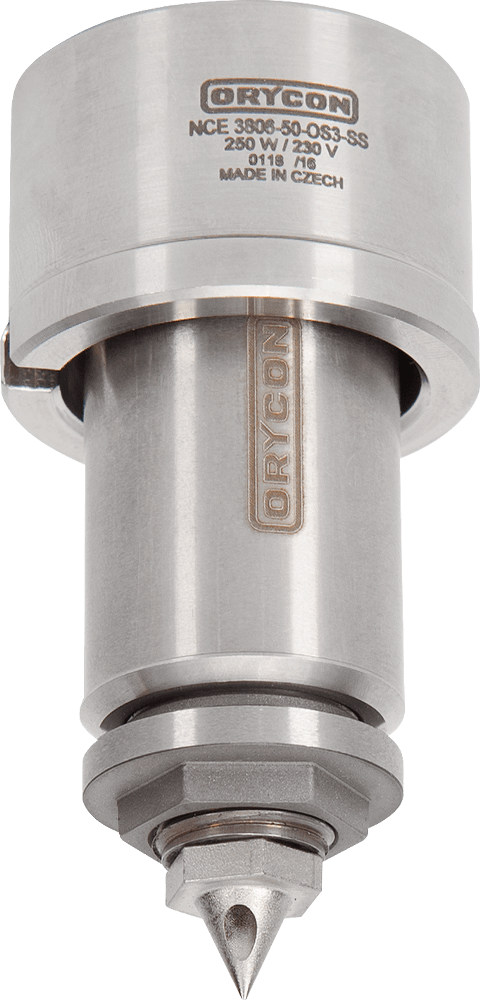

NCE Gating nozzles

Their design predetermines their use for injection molding directly into the mold cavity, where the trace of injection is minimal. Nozzle tips are made in 2 material versions, namely from a copper-berilium alloy, or a composite tip of copper-berilium carbide or steel. The tip group can also be divided into 4 groups according to the nozzle bore, namely 5, 6, 10, 14 and subgroups 12 and 16.

| Class - diameter | 5 | 6 | 10 | 14 |

| Intermediate class - diameter | 12 | 16 |

S-NCE Two-zone nozzles

The basic feature of the two-zone nozzle is a compact body, thermally insulated from its surroundings and controlled by two independent heating zones. The first zone regulates the temperature around the inlet and the second controls the temperature of the melt at the injection point. The insulation of the nozzle body is provided by special rings with minimal thermal conductivity. The design of the two-zone nozzle ensures an uniform temperature throughout the flow without having to exceed the recommended temperature for injection of the material. Constructions using standard nozzles with mounted auxiliary heating are available on the market. This provides two zones however there is space for material leakage. Our compact body eliminates this risk.

DCE Multi-tip nozzles

Plastic injection into the smallest cavities using one multi-tip nozzle DCE or more nozzles placed under a manifold. Construction of this nozzle enables using from 2 to 6 tips. Higher multiplicity is not recommended in order not to exceed spacing between each tip. The DCE version is primarily suitable for injecting of technologically undemanding and unfilled polymers such as polyolefins.

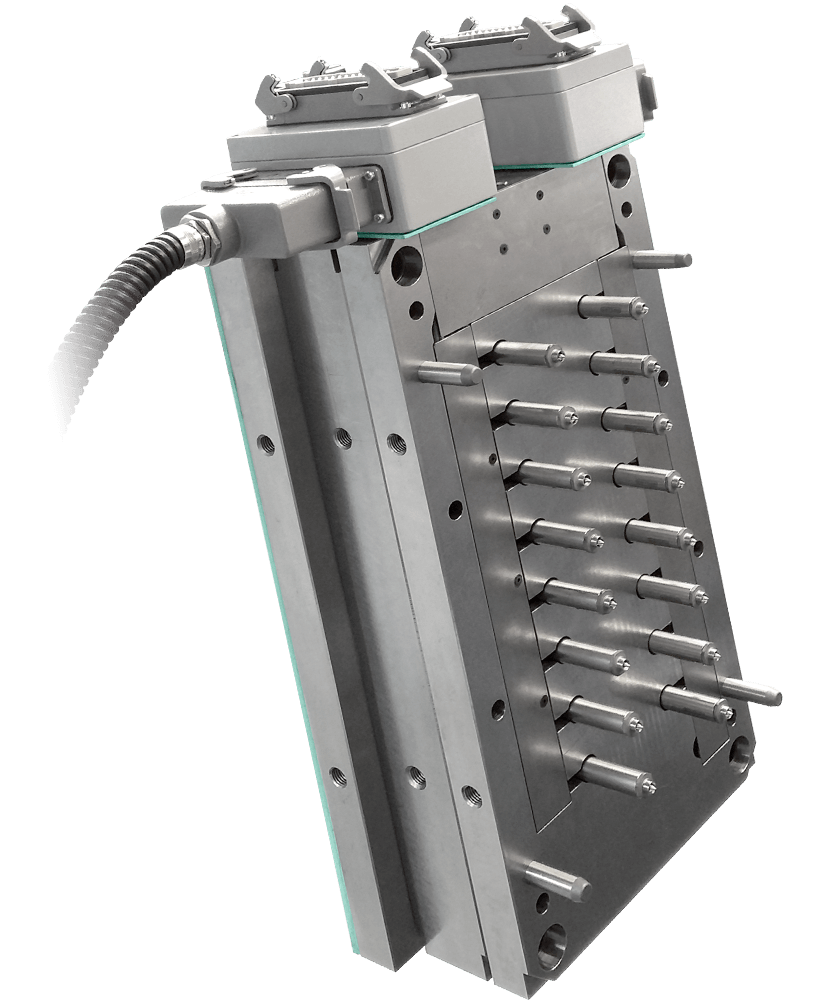

P-NCE Special multi nozzles "Pancake"

Special nozzle for multiple plastic injection without compromises. The nozzle head is designed as a manifold and is equipped with its own heating. Each of the mounted nozzles is also separately heated, which enables full control over the process even for individual cavities. Thanks to individual heating of each nozzle, it is possible to work with more temperature-intensive or filled materials. We also manufacture the P-NCE nozzle in a version with one nozzle located off-axis. This system can be used for filling non-standard cavities.

| Off-axis | 1 nozzle | 2 zones |

| In-axis | 2 nozzles | 3 zones |

| In-axis | 4 nozzles | 5 zones |

MT Threaded nozzles

We supply threaded nozzles in the BCE and NCE version. These types of nozzles are manufactured exclusively in combination with a conventional manifold or the P-NCE system. The upper part of the nozzle does not have a classic head, but a thread that firmly connects the nozzle and the manifold. The advantage of this design is lower heat losses at the location of the conventional nozzle head. However, a solid joint prevents dimensional alignment due to the thermal expansion of the metal. This limits the range of lengths offered compared to standard nozzles.

Are you looking for a suitable solution?

Do not hesitate to contact us.

If none of the mentioned nozzle variants corresponds to your needs, do not hesitate to contact us with a request for custom solutions for non-standard applications. According to design specifications and properties of the material, we are happy to recommend a suitable technology.

CONTACT US